Barcode Generator 128: Ever wondered how those little black and white stripes on packages actually work? It’s way more interesting than you think! This deep dive explores the fascinating world of Code 128 barcode generation, from the nitty-gritty of encoding data to building your own generator and even tackling the security aspects. Get ready to level up your understanding of this ubiquitous technology.

We’ll cover everything from the different Code 128 symbologies (A, B, and C – yeah, there are choices!) and how to pick the right one for your needs, to the best programming languages and APIs to use for generating those crisp, scannable barcodes. We’ll also touch on customizing your barcodes, adding error correction, and even ensuring the security of your data.

Think of it as your one-stop shop for all things Code 128.

Barcode 128 Generator Functionality

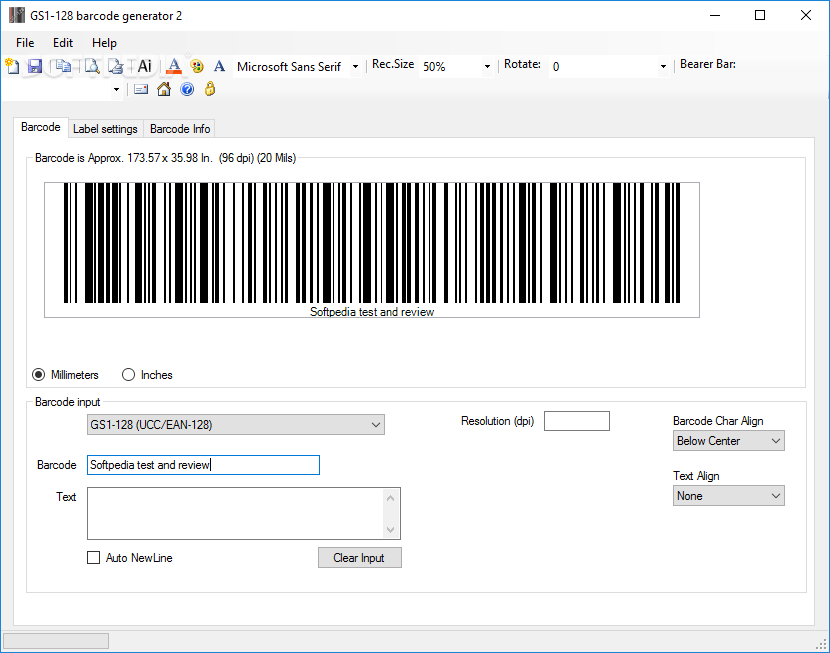

A barcode 128 generator is a software tool that creates Code 128 barcodes from input data. These barcodes are widely used in various industries for efficient tracking and identification of products, packages, and assets because of their high data density and ability to encode a wide range of characters. The generator’s core function is to translate human-readable data into a visual representation, a barcode, that can be scanned and interpreted by barcode readers.The process of encoding data into a Code 128 barcode involves several steps.

First, the generator selects the appropriate Code 128 symbology (A, B, or C) based on the type of data being encoded. Then, it assigns each character in the input data to a corresponding Code 128 character set. Each character is represented by a unique seven-bit code. These seven-bit codes are then converted into a series of bars and spaces of varying widths, creating the visual barcode.

Finally, start and stop characters are added, and a checksum is calculated to ensure data integrity. This checksum is appended to the barcode data and helps verify that the scanned data is accurate.

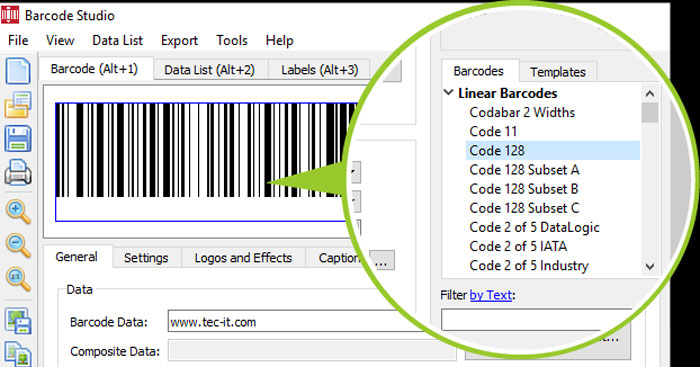

Code 128 Symbologies and Their Applications

Code 128 offers three distinct symbologies: A, B, and C, each designed for specific data types. Choosing the correct symbology is crucial for optimal barcode efficiency. Using the wrong symbology can lead to longer barcodes or the inability to encode certain characters.

- Code 128A: Primarily used for encoding uppercase letters, numbers, and special characters. It’s less efficient for numeric-only data but handles a wider range of characters than Code 128C.

- Code 128B: The most versatile symbology, supporting uppercase and lowercase letters, numbers, and a broad range of special characters. It’s the most commonly used type due to its flexibility.

- Code 128C: Optimized for encoding numeric data in pairs of digits. This makes it the most compact option for purely numerical data, resulting in shorter barcodes. However, it doesn’t support alphanumeric characters.

For instance, a manufacturing company might use Code 128C to encode product serial numbers (purely numeric), while a shipping company might use Code 128B to encode addresses (alphanumeric). A library might use Code 128A to encode book titles that are mostly uppercase.

Data Types Suitable for Code 128 Encoding

Code 128’s versatility allows it to encode a variety of data types, making it suitable for numerous applications. The choice of symbology (A, B, or C) will depend on the nature of the data.

- Numeric Data: Serial numbers, product IDs, quantities, weights, etc. Code 128C is ideal for this.

- Alphanumeric Data: Names, addresses, descriptions, part numbers, etc. Code 128B is the most appropriate choice.

- Special Characters: Punctuation marks, symbols, control characters. Code 128A and B can accommodate these.

Examples include using Code 128 to encode a product’s unique identifier, a batch number, a date of manufacture, or a location code. The specific data encoded depends on the application and the information needed for tracking and identification. A well-designed barcode system, utilizing Code 128 appropriately, ensures efficient and accurate data capture.

Software and API Integration

Integrating a Code 128 barcode generator into your application opens up a world of possibilities, from streamlining inventory management to enhancing e-commerce checkout experiences. The choice of programming language and API significantly impacts the development process, efficiency, and overall performance. Let’s dive into the key considerations.Choosing the right programming language and API for barcode generation is crucial for efficiency and scalability.

The best option depends on your existing infrastructure, developer expertise, and project requirements.

Programming Language Considerations

The selection of a programming language for barcode generation hinges on factors like existing project infrastructure, developer familiarity, and library support. Popular choices include Python, JavaScript, Java, and C#. Python, with its rich ecosystem of libraries like ZBar and pyBarcode, offers a balance of ease of use and powerful features, making it a strong contender for many projects. JavaScript, ideal for web applications, allows for client-side barcode generation, minimizing server load.

Java, known for its robustness and platform independence, is a good choice for enterprise-level applications. C#, primarily used in Windows environments, provides excellent integration with .NET frameworks. Each language has its strengths and weaknesses; the optimal choice depends on the specific project constraints.

Barcode Generator API Comparison

Several APIs provide barcode generation services, each with its own set of features and pricing models. Some popular options include the ZXing library (supporting various languages), and commercial APIs offered by companies specializing in barcode solutions. Open-source options often prioritize flexibility and customization but may require more development effort. Commercial APIs typically offer ease of use, robust support, and often include advanced features like scaling and error correction, but come with a cost.

The choice depends on whether you prioritize cost-effectiveness or a more streamlined development process. For example, a small business might opt for a free, open-source library, while a large enterprise might prefer a paid API with dedicated support and scalability.

Integrating a Code 128 Generator into a Web Application

Integrating a Code 128 generator into a web application typically involves selecting a suitable JavaScript library (like JsBarcode or similar) or utilizing a server-side API. For a client-side approach, the library is included in the web application, generating barcodes directly within the user’s browser. This reduces server load but might impact performance on less powerful devices. A server-side approach, using a language like Python or Node.js, handles barcode generation on the server, sending the generated image to the client.

This approach offers better performance consistency across devices but increases server load. The steps generally involve installing the chosen library or API, implementing the necessary functions to generate the barcode image from the input data, and integrating the generated image into the web application’s user interface.

API Request and Response Structure

A simple API request for barcode generation could follow this structure:

"type": "Code128", "data": "YourDataHere", "format": "png", "width": 200, "height": 100

The response would typically contain the generated barcode image in the specified format, possibly as a base64 encoded string or a file URL. For example:

"status": "success", "barcode": "base64EncodedImageString"

This structure ensures clear communication between the client and the server, facilitating seamless barcode generation within the web application. Error handling mechanisms should be included in the API to provide informative feedback in case of invalid input or other issues.

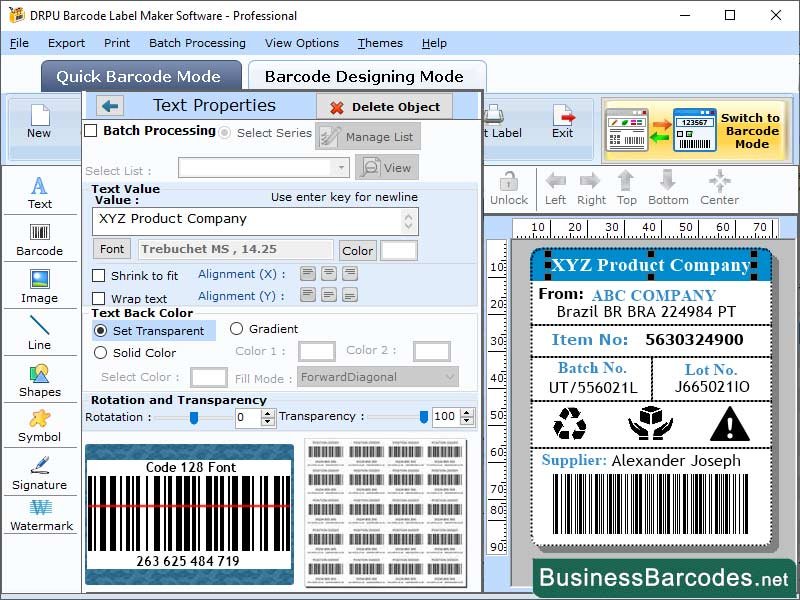

Barcode Image Generation and Customization: Barcode Generator 128

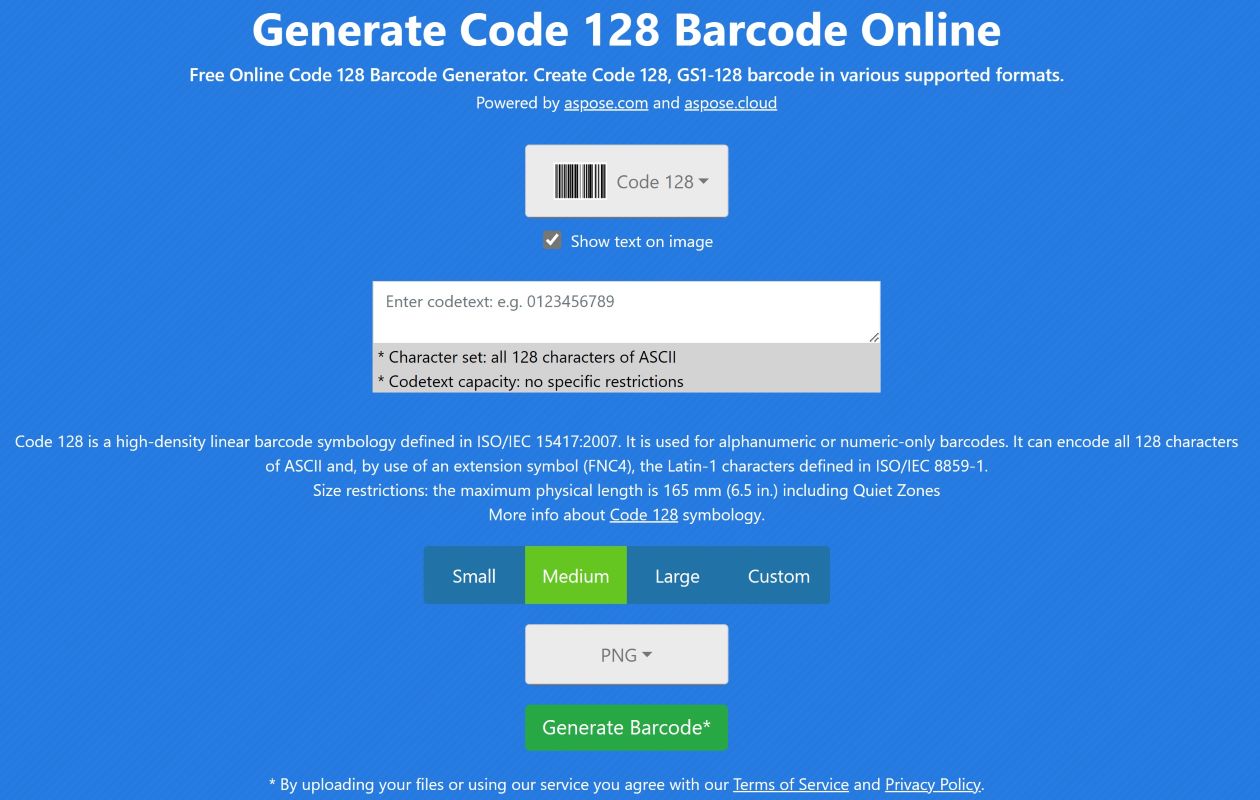

Generating high-quality barcode images is crucial for ensuring readability and professional presentation. This section details methods for creating sharp, customizable barcodes and explores the advantages and disadvantages of different image formats. We’ll also cover adding human-readable text for improved user experience.

High-resolution barcode image generation relies on utilizing libraries or APIs that offer control over image dimensions and resolution. These tools typically allow you to specify the DPI (dots per inch) of the output image, directly impacting its clarity and print quality. Higher DPI values lead to sharper, more detailed barcodes, particularly beneficial for applications requiring small barcodes or those intended for high-resolution printing.

For web applications, the optimal DPI might be lower to balance image quality with file size. For print applications, higher DPI is usually preferable.

Barcode Image Resolution and DPI

The key to generating high-resolution barcode images lies in specifying the desired DPI (dots per inch) during the image creation process. Most barcode generation libraries allow you to set this parameter directly. For example, a setting of 300 DPI will result in a much sharper image than a setting of 72 DPI. The optimal DPI depends on the intended use.

A barcode intended for printing on a high-resolution label printer will benefit from a higher DPI, while a barcode for display on a website might require a lower DPI to reduce file size and loading times. Experimentation is key to finding the sweet spot between quality and file size for your specific application.

Barcode Appearance Customization

Customization options for barcode appearance extend beyond resolution. Most barcode generation libraries provide options to control various aesthetic aspects of the generated image.

Color adjustments include specifying the color of the bars and the background. This can be useful for branding or to improve contrast for better readability. Size customization involves controlling the overall dimensions of the barcode, including the width and height. Precise control over these dimensions is vital for ensuring the barcode fits within its intended space. Text placement options allow you to position human-readable text above or below the barcode, improving user experience and facilitating manual data entry if needed.

Image Format Comparison

Choosing the right image format is crucial for balancing image quality, file size, and compatibility. Each format offers a different trade-off between these factors.

| Image Format | File Size | Quality | Scalability |

|---|---|---|---|

| PNG | Medium | High (lossless) | Good |

| SVG | Small | High (vector-based) | Excellent (scalable without loss of quality) |

| JPG | Small | Medium (lossy compression) | Fair (quality degrades with scaling) |

Adding Human-Readable Text

Adding human-readable text alongside the barcode significantly improves usability. This text duplicates the barcode’s data, allowing for manual verification or entry if barcode scanning fails. Most barcode generation libraries offer options to position this text above or below the barcode, with choices for font, size, and color. The placement should be clear and unobstructed, ensuring easy readability.

For instance, placing the text directly beneath the barcode with sufficient spacing is a common and effective approach.

Error Correction and Validation

Generating reliable Code 128 barcodes requires robust error correction and validation methods. These measures ensure the integrity of the data encoded and prevent misreads by scanning devices. Without them, even small errors can lead to significant problems in inventory management, logistics, and other applications relying on barcode accuracy.Code 128, unlike some other barcode symbologies, doesn’t inherently include built-in error correction.

So you need a barcode generator 128? That’s pretty standard stuff for inventory or shipping. But if you’re feeling creative, you might want to design a custom barcode graphic using some really cool drawing software , then integrate that unique design into your barcode generator 128 output for a truly personalized touch. It’s all about that extra level of customization, right?

Its strength lies in its high data density and the checksum incorporated into the barcode itself. Therefore, error detection and prevention rely heavily on proper validation techniques.

Checksum Verification

The Code 128 barcode includes a checksum character calculated from the encoded data. This checksum acts as a simple but effective error detection mechanism. The scanner verifies the checksum against the data received; a mismatch indicates an error. The calculation involves weighted sums of the character values. A mismatch flags a problem, though it doesn’t pinpoint the error’s location.

For instance, if the data string is “12345”, the Code 128 algorithm would calculate a checksum value (let’s say, ‘X’). The scanner would then calculate the checksum from the scanned data and compare it to ‘X’. A discrepancy signifies a read error.

Data Validation Techniques

Beyond checksum verification, additional validation steps enhance accuracy. This often involves comparing the decoded data against expected values or patterns in a database. For example, a system could check if the decoded product ID exists in its inventory database. Discrepancies would signal a potential barcode generation or scanning error. Furthermore, implementing range checks—ensuring decoded numerical data falls within expected limits—is a valuable validation technique.

Potential Errors and Solutions

Several issues can arise during Code 128 barcode generation. One common problem is incorrect checksum calculation, often due to programming errors or data corruption. This is resolved by thoroughly testing the checksum algorithm and ensuring data integrity. Another potential issue is the use of invalid characters within the data string. Code 128 has a defined character set; characters outside this set will lead to generation errors.

Pre-processing the data to filter out invalid characters is crucial. Finally, insufficient barcode quality (too narrow bars, poor contrast) can cause scanning errors. This is mitigated by adhering to barcode symbology specifications during generation and ensuring sufficient print resolution.

Importance of Checksums in Code 128

The checksum is paramount to Code 128’s reliability. It acts as the first line of defense against errors. While it doesn’t correct errors, it promptly identifies them, allowing for immediate investigation and correction of data entry or scanning issues. Without a checksum, even minor errors could go undetected, leading to costly mistakes in inventory tracking, shipping, or other processes.

The immediate feedback provided by the checksum significantly enhances the reliability of Code 128 applications.

Security Considerations

Generating and using barcodes, while seemingly straightforward, introduces several security vulnerabilities if not handled carefully. Protecting the integrity and confidentiality of data encoded within barcodes is crucial, especially when dealing with sensitive information like inventory tracking in high-value goods or patient data in healthcare. This section details potential risks and mitigation strategies.

Preventing Unauthorized Barcode Generation

Unauthorized barcode generation can lead to counterfeiting, inventory discrepancies, and fraudulent activities. Robust access control measures are essential. This involves restricting access to the barcode generation software and API through secure authentication mechanisms, such as multi-factor authentication (MFA) and role-based access control (RBAC). Implementing strong password policies and regularly auditing user access logs helps maintain control and detect suspicious activity.

Furthermore, employing digital signatures or watermarking techniques on generated barcodes can provide an additional layer of verification and traceability, allowing for the identification of illegitimate barcodes. A well-defined and strictly enforced access control policy is the cornerstone of preventing unauthorized barcode creation.

Securing Barcode Data

The data encoded within a barcode should be treated with the same level of security as any other sensitive data. This means avoiding the encoding of overly sensitive information directly within the barcode itself. Instead, the barcode can contain an identifier that links to a secure database where the actual sensitive data is stored and encrypted. This separation protects the sensitive data from direct exposure.

Regular security audits and penetration testing of the systems handling barcode data are crucial to identify and address vulnerabilities before they can be exploited. Moreover, employing robust data loss prevention (DLP) measures prevents sensitive information from leaving the controlled environment.

Data Encryption for Sensitive Information, Barcode generator 128

When sensitive data must be included in the barcode process, encryption is paramount. This involves using strong encryption algorithms, such as AES-256, to encrypt the data before encoding it into the barcode. The encryption key must be securely managed and protected. Only authorized personnel with the correct decryption key should have access to the decrypted data. Consider using symmetric encryption for efficiency when dealing with large volumes of data, but be aware of the challenges in key management.

Asymmetric encryption can offer better key management but may impact performance. The choice depends on the specific security requirements and operational context. For instance, a hospital might encrypt patient medical record identifiers before incorporating them into barcodes used for medication dispensing, ensuring patient data privacy.

Deployment and Scalability

Deploying a Code 128 barcode generator involves careful consideration of several factors to ensure smooth operation and the ability to handle a potentially large number of requests. This section Artikels a step-by-step deployment process and strategies for scaling to meet growing demand.A well-planned deployment strategy is crucial for a successful Code 128 barcode generator. Ignoring scalability can lead to performance bottlenecks and user frustration as the application grows.

Understanding how to scale efficiently is key to maintaining a robust and reliable service.

Step-by-Step Deployment Guide

The deployment process can vary depending on your chosen environment (on-premise, cloud, etc.), but a general Artikel includes these steps: First, you’ll need to build your barcode generation application. This might involve coding in a language like Python or Java, using a library like ZXing or similar. Next, you’ll need to set up your chosen server environment, configuring necessary dependencies and ensuring compatibility.

Testing your application thoroughly before deployment is critical to identify and fix any bugs or performance issues. Finally, deploy your application to the chosen environment, carefully monitoring its performance and making any necessary adjustments.

Scaling Strategies for High-Volume Requests

Handling a large number of requests efficiently requires proactive planning. One approach is vertical scaling, which involves upgrading the server’s hardware (more RAM, faster CPU, etc.). However, this has limitations. Horizontal scaling, adding more servers to distribute the load, offers greater flexibility and scalability. This typically involves using a load balancer to distribute incoming requests across multiple servers.

Employing microservices architecture, breaking down the application into smaller, independent services, can improve scalability and resilience. Each service can be scaled independently based on its specific needs.

Load Balancing and Caching for Performance Optimization

Load balancing is essential for distributing incoming requests evenly across multiple servers, preventing any single server from becoming overloaded. Common load balancing techniques include round-robin, least connections, and IP hash. Caching frequently accessed barcode images significantly reduces the load on the generation process. A caching layer can store generated barcodes, serving them directly from the cache when available, thus minimizing the number of times the barcode needs to be generated.

This improves response times and reduces server load.

Cloud-Based Deployment Solutions

Cloud platforms offer several advantages for deploying barcode generators, including scalability, reliability, and cost-effectiveness. Amazon Web Services (AWS), Google Cloud Platform (GCP), and Microsoft Azure all provide services like virtual machines, container orchestration (Kubernetes), and serverless functions that can be used to deploy and scale barcode generation applications. For instance, deploying the application as a serverless function on AWS Lambda allows for automatic scaling based on demand, ensuring efficient resource utilization and cost optimization.

Using containerization with Docker and Kubernetes provides portability and ease of scaling across multiple cloud providers or on-premise environments.

Real-World Applications of Code 128

Code 128, with its high density and ability to encode a wide range of characters, has become a ubiquitous barcode symbology across numerous industries. Its versatility and efficiency make it a popular choice for applications requiring robust data representation and reliable scanning. Let’s explore some key areas where Code 128 shines.

Industries Using Code 128 Barcodes

Code 128’s broad character set and high density make it ideal for a wide array of industries. Its ability to encode numbers, letters, and special characters allows for diverse applications across sectors. For example, manufacturing utilizes Code 128 to track components throughout the production process, ensuring efficient inventory management and quality control. Retailers leverage Code 128 for product identification at the point of sale, facilitating streamlined checkout and inventory tracking.

The healthcare industry uses Code 128 to label medical supplies and track patient samples, enhancing safety and accuracy. Logistics companies rely on Code 128 for efficient package tracking and sorting, optimizing delivery processes. These are just a few examples of the many sectors that benefit from Code 128’s versatility.

Code 128 in Supply Chain Management

In supply chain management, Code 128 plays a crucial role in tracking goods throughout their journey from origin to final destination. Each package or pallet can be uniquely identified with a Code 128 barcode containing information such as product ID, batch number, and shipping details. This allows for real-time tracking of inventory, reducing delays and improving efficiency. Furthermore, Code 128’s error detection capabilities help minimize discrepancies and prevent losses during transit.

For instance, a large distribution center might use Code 128 to track thousands of packages simultaneously, automatically sorting and routing them to their respective destinations based on the barcode data. This automated system improves accuracy and speed compared to manual processes.

Code 128 Applications in Healthcare and Logistics

The healthcare industry utilizes Code 128 for accurate identification and tracking of medical supplies, pharmaceuticals, and patient samples. This ensures proper medication administration, prevents errors, and improves patient safety. For example, Code 128 barcodes on blood bags ensure accurate identification and tracking, reducing the risk of transfusion errors. Similarly, in logistics, Code 128 enables efficient tracking of shipments, facilitating real-time monitoring of package location and status.

This allows for proactive management of delays and improved customer service. Imagine a courier company using Code 128 to track every package on its delivery routes; the data provides a clear picture of package location and delivery status, improving efficiency and customer satisfaction.

Benefits of Code 128 Over Other Barcode Symbologies

Code 128 offers several advantages over other barcode symbologies in specific scenarios. Compared to Code 39, Code 128 boasts a higher density, allowing for more data to be encoded in a smaller space. This is particularly beneficial in applications with limited space for barcodes, such as small medical vials or densely packed pallets. Its extended character set, including uppercase and lowercase letters, numbers, and special symbols, makes it more versatile than Code 12, which primarily handles numeric data.

Furthermore, Code 128’s built-in error detection capabilities improve data integrity and reliability compared to simpler barcode symbologies. In situations requiring high data density and a broad character set, such as tracking pharmaceutical products with detailed batch information, Code 128’s superior capabilities are clear.

Comparison with Other Barcode Standards

Choosing the right barcode standard for your application can feel like navigating a maze. Different standards offer varying levels of data capacity, readability, and compatibility with existing systems. This section compares Code 128 with other popular barcode standards, highlighting their strengths and weaknesses to help you make an informed decision.

Code 128 vs. EAN/UPC

Code 128, EAN (European Article Number), and UPC (Universal Product Code) are all widely used barcode symbologies, but they cater to different needs. EAN and UPC are primarily designed for retail applications, focusing on identifying products at the point of sale. They have fixed lengths and are limited in the amount of data they can encode. Code 128, on the other hand, is a much more versatile symbology, capable of encoding a far greater range of characters and data lengths.

This makes it ideal for applications requiring more complex information, such as inventory tracking in warehouses or asset management.

Strengths and Weaknesses of Each Standard

Let’s break down the strengths and weaknesses:

| Barcode Standard | Strengths | Weaknesses |

|---|---|---|

| Code 128 | High data density, variable length, alphanumeric capability, supports many character sets | Can be more complex to implement than EAN/UPC, requires more sophisticated scanners in some cases |

| EAN/UPC | Widely adopted, simple to implement, readily scanned by most point-of-sale systems | Limited data capacity, fixed length, primarily numeric |

| QR Code | High data capacity, can store various data types (text, URLs, images), error correction capabilities | Larger size than linear barcodes, may require specialized scanners for some applications |

Factors to Consider When Choosing a Barcode Standard

Several factors influence the choice of barcode standard. These include the type and amount of data to be encoded, the required level of error correction, the cost of implementation, the compatibility with existing scanning equipment, and the overall industry standards in your specific sector. For instance, a retail setting might favor EAN/UPC due to widespread scanner compatibility, while a manufacturing environment might opt for Code 128’s greater data capacity for tracking individual components.

If you need to store large amounts of diverse data, a 2D barcode like a QR code could be the best solution.

Troubleshooting Common Issues

Generating Code 128 barcodes might seem straightforward, but several issues can crop up, leading to scanning failures or unexpected results. This section covers common problems and their solutions, helping you create reliable and scannable barcodes. Understanding these troubleshooting steps will save you time and frustration in the long run.

Barcode Scanning Errors

Barcode scanning errors often stem from poor barcode quality or incorrect encoding. A poorly printed barcode, for instance, might have smudged lines or inconsistent spacing, making it difficult for scanners to interpret. Similarly, errors in the data encoding itself can lead to incorrect or unreadable barcodes.

Solutions involve checking the barcode’s print quality. Ensure the printer resolution is high enough, the print is clean and clear, and the contrast between the bars and spaces is sufficient. If the problem persists, verify the data being encoded is correct and hasn’t been corrupted during transmission. A visual inspection of the generated barcode, comparing it to known good examples, can often pinpoint the problem.

Tools exist that can analyze barcode images for quality and identify potential issues.

Encoding Issues

Incorrect data encoding is a frequent source of barcode generation problems. This includes using the wrong character set or failing to properly escape special characters. For example, using characters outside the Code 128 character set will lead to an invalid barcode.

Troubleshooting involves meticulously reviewing the input data. Ensure the data is properly formatted and conforms to the Code 128 standard. Using a Code 128 character set reference chart helps confirm that all characters used are supported. Many barcode generation libraries offer validation features; utilize these to identify potential encoding problems before generating the barcode image. If custom encoding is implemented, thoroughly test the encoding algorithm with known good and bad input data to verify its correctness.

Debugging Barcode Generation in Different Programming Languages

Debugging barcode generation problems varies slightly depending on the programming language used. However, the core principles remain consistent.

In Python, for example, using a print statement to display the data being encoded before generating the barcode can help pinpoint errors. Integrated Development Environments (IDEs) offer debugging tools to step through the code and inspect variables at runtime. Similar debugging techniques are applicable in other languages like Java, C#, or JavaScript. Using logging statements at various stages of the barcode generation process can provide valuable insights into the flow of data and help identify the point of failure.

Furthermore, employing unit testing, where small, isolated parts of the barcode generation code are tested individually, is a valuable approach to catch errors early in the development process. This allows for focused troubleshooting and quicker identification of the root cause of issues.

Advanced Features and Techniques

Taking our barcode generation capabilities to the next level involves exploring some pretty cool advanced features and techniques. These enhancements go beyond basic barcode creation, allowing for more visually appealing and functionally rich applications. We’ll delve into ways to boost your barcodes’ visual impact and integrate them seamlessly with other technologies.

Incorporating Logos or Additional Graphics into Barcode Designs

Adding logos or other graphics to barcodes can significantly improve brand recognition and visual appeal. This is usually achieved by placing the logo alongside the barcode, carefully ensuring sufficient spacing to prevent interference with the barcode’s readability. The key here is finding the right balance—a large logo might obscure the barcode, while a tiny logo might be ineffective.

Design software often provides tools to precisely position and size elements, allowing for a professional-looking final product. For instance, imagine a grocery store loyalty card with its logo subtly integrated next to the Code 128 barcode. This creates a more cohesive and memorable branding experience for the customer. The process typically involves generating the barcode separately, then importing both the barcode and the logo into an image editor or design program where they can be combined and exported as a single image.

Generating QR Codes that Link to Code 128 Barcodes

QR codes offer a convenient way to link to additional information. You can generate a QR code that, when scanned, directs the user to a website containing detailed product information associated with the Code 128 barcode. This allows for a seamless integration of physical and digital data. Consider a scenario where a QR code is placed next to a Code 128 barcode on a product label.

Scanning the QR code could lead to a website providing detailed specifications, reviews, or even a video demonstration of the product. The technical implementation involves using separate libraries or APIs for generating both Code 128 barcodes and QR codes. The QR code data would contain a URL linking to the relevant Code 128 information.

Creating Dynamically Generated Barcodes Based on User Input

Dynamic barcode generation is crucial for applications requiring unique barcodes for each transaction or item. This involves designing a system where the barcode data is generated on-the-fly based on user input, such as an order number, product ID, or serial number. A common example is e-commerce platforms generating unique shipping labels with dynamic barcodes for each order. The backend system would take the user’s input, generate the Code 128 barcode data, and then render the barcode image.

This requires a robust backend system capable of handling user input, barcode generation, and image output. The process usually involves using a programming language (like Python or Java) with a suitable barcode generation library.

Implementing Data Compression Techniques to Optimize Barcode Size

For applications where barcode size is a critical factor (like on small labels or tags), data compression techniques can be beneficial. While Code 128 is already relatively efficient, compressing the data before encoding it into the barcode can slightly reduce its size. This is especially relevant when dealing with large amounts of data. However, it’s important to balance compression with the need for reliable data integrity.

Lossy compression methods (which discard some data to reduce size) should generally be avoided to ensure the barcode can be accurately scanned. Lossless compression, such as run-length encoding or Huffman coding, could be considered but might not yield significant size reductions for typical Code 128 data. The optimal approach would depend on the specific application and the trade-off between size and reliability.

Concluding Remarks

So, there you have it – a comprehensive look at the world of Barcode Generator 128. From understanding the core functionality and choosing the right symbology to mastering image generation, customization, and security, we’ve covered the essentials. Remember, the right barcode generator can streamline your processes, improve efficiency, and even enhance security. Now go forth and generate some awesome barcodes!

Question & Answer Hub

What’s the difference between Code 128A, B, and C?

Each Code 128 symbology (A, B, C) handles different data types. A is best for uppercase letters and special characters, B for a mix of upper and lowercase, numbers, and symbols, and C is optimized for numbers.

Can I generate barcodes offline?

Yes! Many barcode generator libraries and software work offline. You just need to install the necessary software or have a locally hosted solution.

How do I choose the right resolution for my barcode image?

Higher resolution (e.g., 300 DPI) is generally better for printing, while lower resolutions might suffice for digital displays. Consider the printing method and scanning distance.

What happens if a barcode is damaged or partially obscured?

Error correction techniques can help, but severe damage can lead to scanning failures. The level of error correction you implement will influence how much damage a barcode can sustain and still be read.

Are there any legal considerations for using barcodes?

Generally, the barcode symbologies themselves are not subject to legal restrictions. However, the data encoded in the barcode might be subject to regulations depending on its content (e.g., product information, tracking numbers).